Innolite: Ultra-Precision Diamond Turning Machines

A Partnership Built for Innovation

The strategic partnership between Innolite, a leader in ultra-precision machining technology, and us - marks a pivotal advancement for precision manufacturing in the UK and Ireland. This collaboration merges Innolite’s cutting-edge diamond turning machines and optics technologies with our deep industry expertise and customer-focused service.

Together, we aim to elevate performance standards across industries such as optics, aerospace, automotive, and advanced manufacturing, delivering the high-accuracy solutions modern manufacturers require. With an emphasis on innovation, technical support, and local service, this alliance ensures companies in the UK are equipped to meet rising demands for precision and complexity - now and into the future.

Innovations for Optics and Light

Innolite is at the forefront of developing and delivering ultra-precision machines for optics manufacturing, setting new industry standards in both precision and productivity.

Innolite's Advanced Diamond Turning Machines for Optical Components

.png?width=600&height=500&name=Innolite%20IL200%20(7).png)

IL200

A small compact and highly efficient machine for mold pins, ophthalmic products or any other ultra-high accuracy small parts.

Key Advantages:

- DirectDrive3D technology, enables the IL200 to achieve unmatched free form machining performance.

- Surface roughness as low as <0.5 nm Ra

- Natural granite base for excellent accuracy .

Self-levelling pneumatic vibration isolation system - Programming Resolution 1 nm linear (0.01 nm optional), 0.0000001° rotary.

Long term stability and highest repeatability is achieved with integrated air conditioning system, water & oil temperature management, and active pressure control.

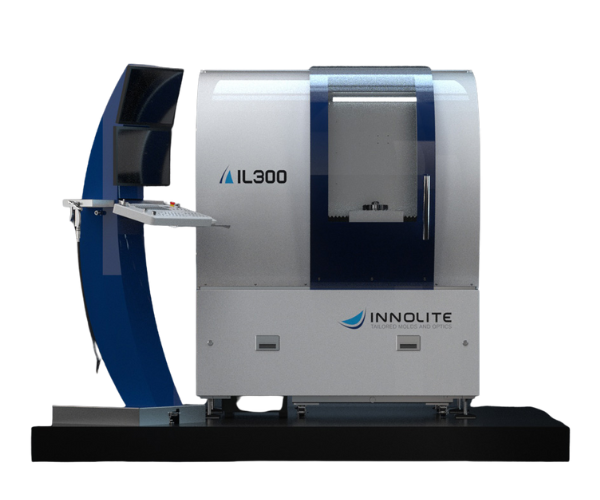

IL300

The leading ultra-precision diamond lathe for highly productive, highly flexible optics manufacturing.

Key Advantages:

- Ultra-precise diamond lathe for optics production

- Natural granite base for excellent accuracy

-

- Self-levelling pneumatic vibration isolation system (option: passive or electronically controlled active levelling)

- Consistently integrated zero-point clamping systems with submicron accuracy, a stainless-steel housing and a highly dynamic lightweight construction for maximum dynamics.

- Vibration Isolation Self levelling pneumatic isolation system (option: passive or electronically controlled active levelling)

- Applications for this model range from standard diamond turning to free-form manufacturing and microstructure generation to diamond turning of steel and infrared materials with ultrasonic support (ILSONIC).

- Self-levelling pneumatic vibration isolation system (option: passive or electronically controlled active levelling)

IL400L

The IL400L is the first ultra-precision machine designed for next level laser processing of brittle materials beyond conventional diamond turning. The IL400L paves the way for next level ultra-precision machining

Technical Data:

- Ultra-precise diamond lathe for optics production.

- Natural granite base for excellent accuracy

- Self-levelling pneumatic vibration isolation system

- It‘s unique certified laser safety concept allows for autonomous and automated machine operation of up to 8.5 hours.

- Flexibility in automation for small and medium sized components

- The versatile platform can accommodate both selective laser etching of fused silica (ILSLE) and direct ablation with the femtosecond laser, as well as laser assisted diamond machining with ILPAC.

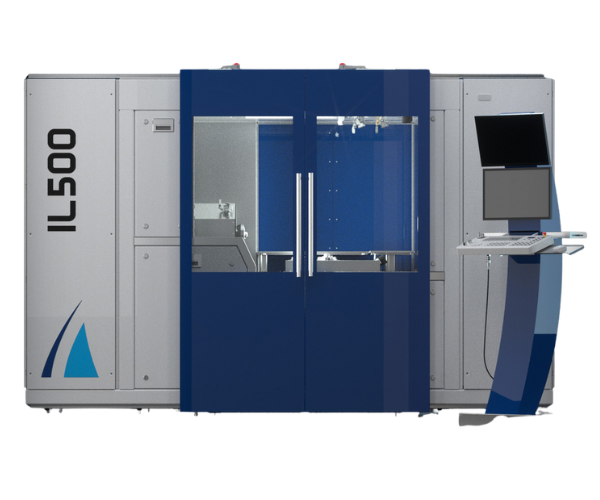

IL500

In addition to large components with diameters of up to 500 mm, the IL500 offers unique options for simultaneous process equipment or parallelization of processes.

Technical Data:

- Handles components up to 500 mm diameter

- Natural granite base for excellent accuracy.

- Self-levelling pneumatic vibration isolation system.

- Available with three or four ultra-precision axes, spherical, free-form and also micro-structured optics can be efficiently manufactured.

- Integrated measurement technology enables the inline characterization of surfaces with direct compensation.

- Prepared for loading with robots, the machine is the ideal platform for automated series production.

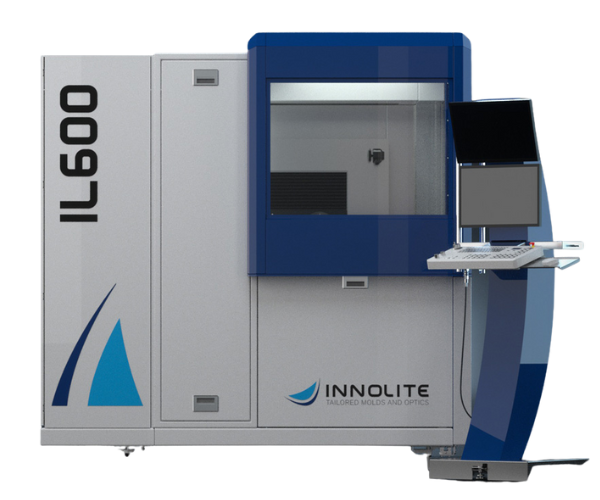

IL600

The IL600 is a four- or optionally five-axis ultra-precision machining center for highly productive optics production.

Technical Data:

- 4-6 axes for turning, milling, grinding, and measuring (max. 600 mm)

- Natural granite base for excellent accuracy.

- Self-levelling pneumatic vibration isolation system

- The IL600 enables the combination of diamond turning and free-form turning, planing and milling as well as the grinding of optical surfaces. A range of contact and non-contact sensors that can be fully integrated into the machine and the control system for advanced component characterisation.

- The integrated NanoGrip zero-point clamping system is the state-of-the-art in flexibility and productivity for diamond machining systems.

IL1200

The IL1200 is a vertical diamond turning platform to machine large scale optical mirrors of diameters up to 1.2 m.

Technical Data:

- The vertical arrangement of the main spindle allows for stress optimized mounting of mirror structures and precision alignment without influences of gravitational forces

- Natural granite base for excellent accuracy

- The fully hydrostatic supported portal structure allows for ultimate precision in diamond turning

- NanoGrip interfaces at the Z-slide ensure the adaptation of different toolholders, other fixtures or metrology sensors to enable complex machining sequences.

- Supported by Innolite’s advanced diamond turning software, ILCAM, compensation and characterization are feasible in one platform.

.png?width=600&height=500&name=_Innolite%20IL1600%20(1).png)

IL1600

The IL1600 is a vertical diamond turning platform to machine large scale optical mirrors of diameters up to 1.6 m.

Technical Data:

- Natural granite base for excellent accuracy.

- The vertical arrangement of the main spindle allows for stress optimized mounting of mirror structures and precision alignment without influences of gravitational forces.

- Self-levelling pneumatic vibration isolation system.

- NanoGrip interfaces at the Z-slide ensure the adaptation of different toolholders, other fixtures or metrology sensors to enable complex machining sequences.

- Supported by Innolite’s advanced diamond turning software, ILCAM, compensation and characterization are feasible in one platform.

Innolite's Advanced Alignment Turning Machines for Optical Components

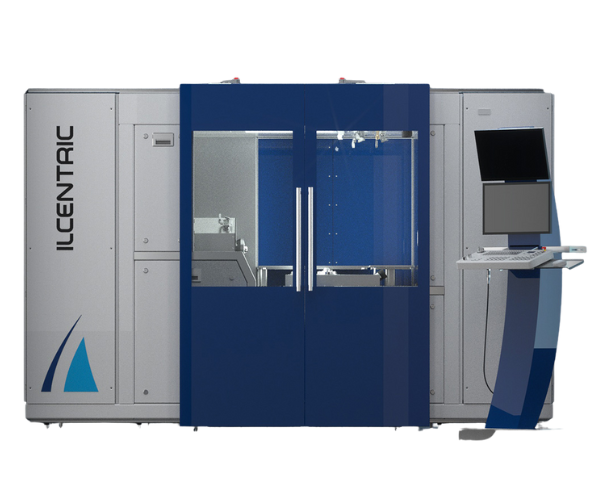

ILCENTRIC300

The ILCENTRIC300 is the leading ultra-precision machine platform for high-performance alignment of mounted lenses with diameters of up to 250 mm.

Various integrated optical and tactile sensors enable the centering of all relevant modern optics. The ILCENTRIC does not use a conventional center chuck, but a unique dynamic turning process to correct the alignment of the optical axes from lens to frame. As a result, the machine can be used not only for alignment turning, but also for the diamond turning process and the high-precision manufacturing of mechanical components.

The machine utilization can thus be individually adjusted between alignment turning and ultra-precise manufacturing in order to minimise depreciation periods.

ILCENTRIC500

Based on the experience with the ILCENTRIC300, the ILCENTRIC500 has been developed for aligning large lenses with diameters of up to 400 mm. Furthermore, the machine offers space to integrate additional, permanently equipped measuring technology or processes such as the engraving of reference marks, the milling of reference grooves or automated assembly using robots.

The ILCENTRIC does not use a conventional center chuck, but a unique dynamic turning process to correct the alignment of the optical axes from lens to frame. As a result, the machine can be used not only for alignment turning, but also for the diamond turning process and the high-precision manufacturing of mechanical components.

The machine utilisation can thus be individually adjusted between alignment turning and ultra-precise manufacturing in order to minimize depreciation periods.

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

.png?width=2563&height=2351&name=KERN-Ametek-logo-rot-schwarz%20(1).png)

.png?width=500&height=200&name=PEMtec%20Logo%20(1).png)

.png?width=500&height=200&name=Benzinger%20Logo%20(1).png)

Interested In Our Products?

Get access to our wide range of product brochures

Latest From The Blog

2 min read

Applications Driving Demand For Ultra-Fine Carbide Grades

Jan 8, 2026 by Rainford Precision

5 min read

Electrochemical Production Of Precision Parts At Scerox EDM Technology

Jan 5, 2026 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)