Carl Benzinger Lathes:

Precision Engineering for

Advanced Manufacturing

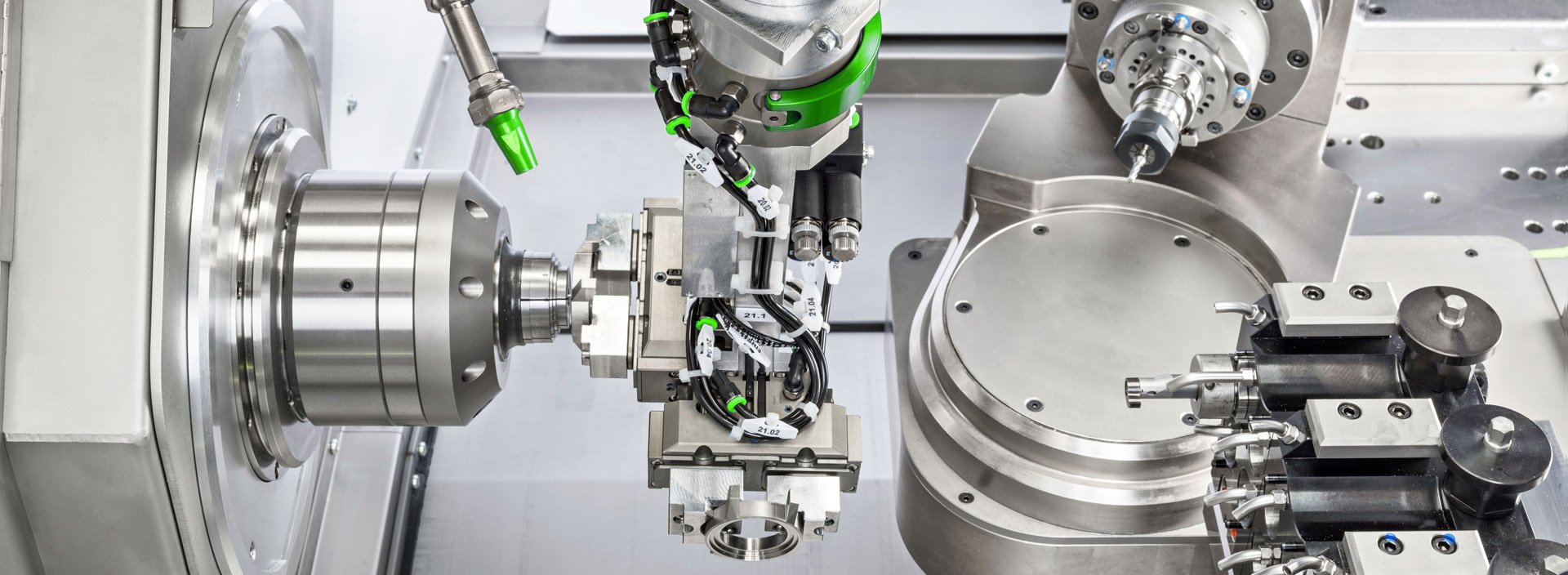

Benzinger: Precision Engineering Heritage and Innovation

Founded in 1916, Carl Benzinger began as a manufacturer of turning and milling machines in Pforzheim, Germany, initially serving the jewellery and watchmaking industries. By 1941, under the management of the Jehle family, the company transitioned into CNC lathe production, establishing itself as a leader in high-precision machining.

Today, Benzinger operates as a globally recognized organisation, specializing in ultra-precision CNC lathes and milling machines for industries such as medical, aerospace, automotive, optics, and watchmaking.

Benzinger’s philosophy centres on German-engineered quality, modular machine design, and customer-specific automation solutions, ensuring maximum productivity and unmatched precision.

Product Range

High-Precision CNC Turn-Mill Centre

DoLittle Series - Ultra-Precision for Small Parts Designed for Micro-machining

The DoLittle series excels in high-speed, high-accuracy production of small components (up to 26mm diameter).

Key Advantages:

- Spindle speeds up to 15,000 rpm (main spindle).

- Diameter 42mm Bar Capacity.

- Tool change accuracy < 0.01 mm (external pre-setting possible).

- Modular automation (robotic loading, bar feeders).

- Thermally stable design for sub-micron precision (< 0.5µm runout) .

- Fanuc/Siemens controls with Industry 4.0 integration (smart monitoring, remote diagnostics).

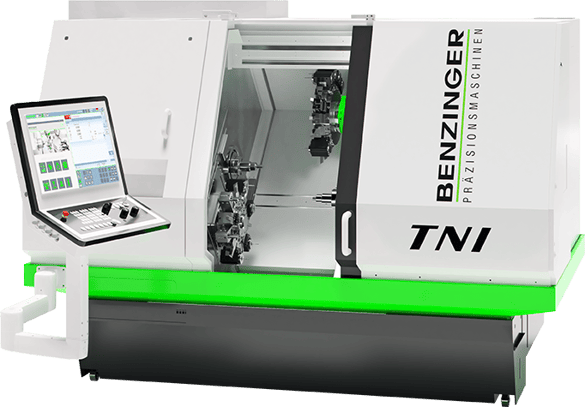

TNI Series – Complex Multi-Tasking Lathes

Focused on complete machining (turning, milling, drilling), the TNI series features:

Key Advantages:

- 15,000 rpm spindles, both Main and Counter spindles (radial/axial runout < 0.7µm).

- Fanuc/Siemens controls with Industry 4.0 integration (smart monitoring, remote diagnostics)

GoFuture Series – Complex Multi-Tasking with 5 axis Capability

High precision and a highly flexible modular design for the complete production of highly accurate complex components.

Key Advantages:

- 15,000 rpm spindles, both Main and Counter spindles (radial/axial runout < 0.7µm).

- Diameter 42mm Bar Capacity.

- Fanuc/Siemens controls with Industry 4.0 integration (smart monitoring, remote diagnostics).

- Swivelling Five Axis Unit with HSK40 Spindle Connection and 30000 rpm high precision spindle. Tool Magazine Capacity up to 100 tool positions.

- Highly flexible modular design and easily integrated automation via Barfeed System or Robot Loading.

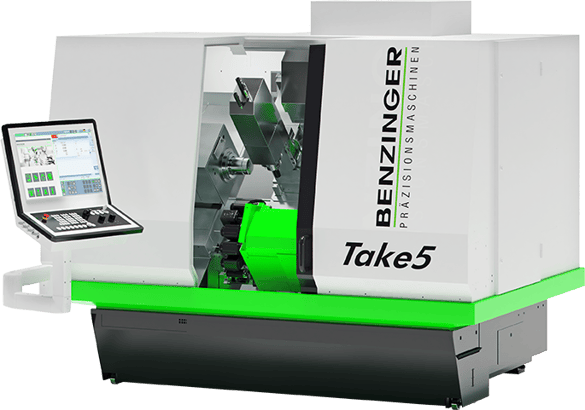

Take 5 Series - Complex Multi-Tasking with 5-axis Capability

High precision and a highly flexible modular design for complete production of highly accurate complex components.

Key Advantages:

- 8,000 rpm spindles, both Main and Counter Spindle (radial/axial runout < 0.7µm).

- 16 Position VDI25 Turret with Y Axis.

- Fanuc/Siemens controls with Industry 4.0 integration (smart monitoring, remote diagnostics).

- Swivelling Five Axis Unit with HSK40 Spindle Connection and 30000 rpm high precision spindle. Tool Magazine Capacity up to 52 tool positions.

- Easily integrated automation via Bowl Feeder System or Robot Loading.

What Sets Benzinger Apart?

Extreme Precision & Stability

- High Accuracy Spindles (roundness and runout < 0.5µm).

- Linear guideways and thermally compensated structures for nanometer-level accuracy.

Integrated Hard Turning & Grinding

- Hard turning (up to 72 HRc) replaces grinding, reducing costs and cycle times.

- Mirror finishes (< 3µm) are achievable.

- Dry machining eliminates the requirement for coolant.

- Combined hard turning + grinding for sealing surfaces (e.g., valve seats).

High-Speed Machining Capabilities

- Main and Counter Spindle: 15,000 rpm.

- 5-axis milling spindle: 30,000 rpm (HSK-40).

Deep Hole Drilling

- Gun Drilling with 100 bar coolant pressure.

- L/D ratio > 30 (e.g., medical implants, aerospace components).

Industry 4.0 & Smart Manufacturing

- Benzinger Smart Panel: Real-time tool monitoring, predictive maintenance, and remote access.

- CB-Apps: Digital workflows for setup optimisation, document management.

Rainford Precision’s Unique Value

At Rainford, we’re proud to be the exclusive UK partner for Benzinger, bringing their precision lathes to manufacturers up and down the country. Our team has decades of experience in precision tooling and micro-manufacturing solutions, making us uniquely positioned to support your needs from initial enquiry through to machine delivery, set up training and post-sale service.

We have:

- Technical expertise – We understand the demands of precision engineering across multiple industries and have the technical know-how to advise you on what works best.

- Hands-on support – From test cutting to installation and training, we work closely with our customers to ensure a successful process from start to finish.

- Tooling compatibility – As precision tooling specialists, we can advise you on the optimal combination of machine and tooling accessories to achieve the desired result.

- After-sales care – Our commitment doesn’t end with delivery. We provide ongoing advice and support to keep your operation running smoothly.

Contact us to discover more about how Benzinger Lathes can benefit your business.

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

.png?width=2563&height=2351&name=KERN-Ametek-logo-rot-schwarz%20(1).png)

.png?width=500&height=200&name=PEMtec%20Logo%20(1).png)

.png?width=500&height=200&name=Benzinger%20Logo%20(1).png)

Interested In Our Products?

Get access to our wide range of product brochures

Latest From The Blog

2 min read

Applications Driving Demand For Ultra-Fine Carbide Grades

Jan 8, 2026 by Rainford Precision

5 min read

Electrochemical Production Of Precision Parts At Scerox EDM Technology

Jan 5, 2026 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)