Ring Sawing Machines

mySaw - Automated Ring Sawing Machine

This fully automatic ring sawing system is designed for customised, order-based production, offering the following key features:

- Automated Processing: Performs order-specific sawing of ring blanks in various dimensions.

- High-Capacity Magazine: Equipped with a loader that holds either 36 or 54 tubes of different precious metal alloys.

- Flexible Data Input: Accepts order data automatically from an ERP system, a customer's ring configurator, or via manual entry.

- Integrated Widening: Includes a device that automatically expands sawn rings by several sizes, depending on the material.

- Seamless Integration: Unloads widened rings onto bars that are directly compatible with Benzinger GORing and DOLittle-TKR lathes.

Lathes For Jewellery and Watches

GORing Lathes

The GORing lathe is a specialised turning center designed exclusively for crafting rings, with an uncompromising focus on achieving the highest surface quality. It utilizes diamond tools to produce a brilliant, shiny finish directly during the turning process.

The GORing R2 model transforms a blank into a finished ring in a single, complete operation. Its high productivity and flexibility come from an automatic loader/unloader, a vast array of turning tools, a rotary table (B axis), and milling spindles.

An optional Y-axis greatly simplifies setup for diamond tools by allowing easy, automated height adjustment. Furthermore, the machine is exceptionally user-friendly, featuring parameterised CNC programs and a special interface for intuitive operation and programming.

DOLittle TKR Lathe

The DOLittle TKR CNC turning lathe is a compact, all-in-one solution for bright-turning wedding rings. It achieves a flawless interior and exterior finish on a minimal footprint. Operating with manual or full automation, this machine meets the highest surface quality standards by employing diamond tools to produce a glossy finish directly during turning. Combining maximum flexibility and productivity, the DOLittle TKR is effortlessly controlled through intuitive, parameterised CNC programs and a custom user interface.

GOFuture Lathe

The GOFuture B3 and B6 are high-precision, automated lathes with main and counter spindles for machining rings from bar or tube stock. Designed for exceptional productivity and flexibility, they meet the highest standards for surface quality through high-gloss turning.

The B3 features a single tool turret with specialised discs for diamond and PCD tools, while the B6 adds a second turret for simultaneous machining on both spindles. Both models use a VDI 25 interface to accommodate driven milling tools and are compatible with an automatic unloading device. With a capacity for bars up to Ø42 mm and 800 mm in length, they handle all ring sizes. An optional Y-axis significantly reduces setup time for diamond tools by allowing easy NC-controlled height adjustment. Intuitive operation is ensured through parameterised CNC programs and custom user interfaces.

Mill Turn Center For Jewellery and Watches

GOFuture BX Mill/Turn Centre

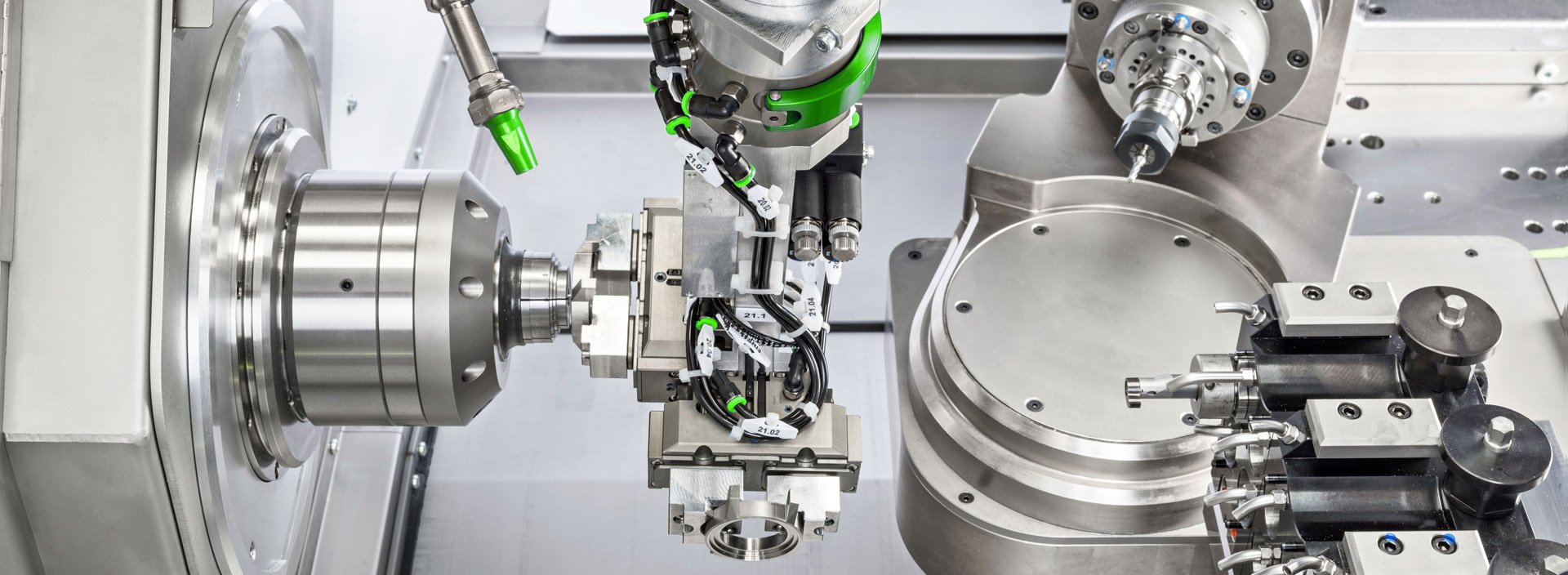

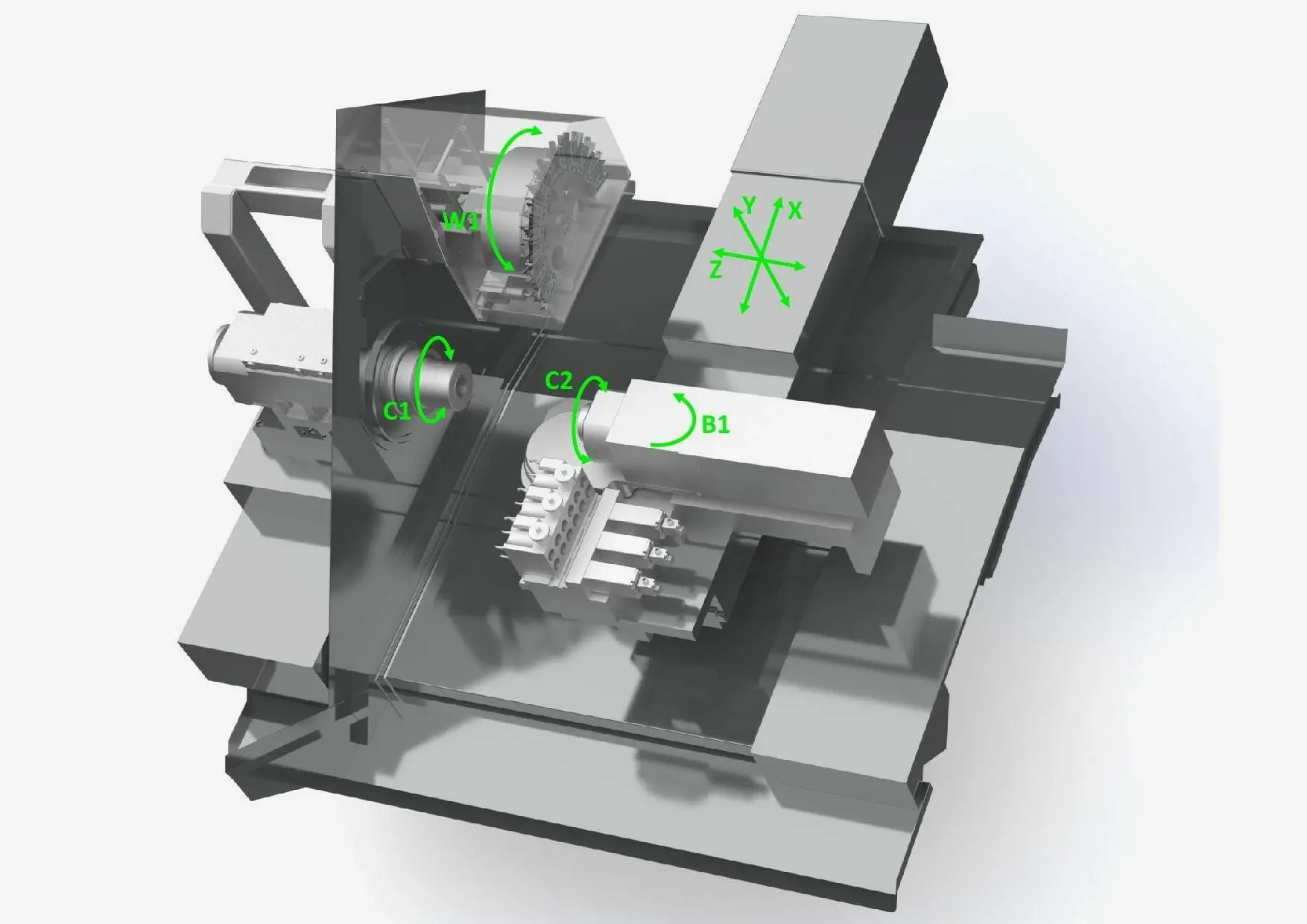

The GOFuture BX mill turn center integrates the renowned precision of our legacy lathes with the advanced capabilities of a modern 5-axis milling machine. This CNC center is highly efficient for both small and large production runs. Its innovative design features rapidly interchangeable linear blocks for turning tools and a standard tool changer for the milling spindle, enabling swift and flexible retooling without sacrificing precision or rigidity.

It offers a range of high-precision turning spindles (26-42 mm diameter) with exceptional run-out accuracy (< 0.7µm) and speeds up to 8,000 rpm, paired with versatile clamping systems for both powerful and delicate workpiece handling. A Y-axis expands machining possibilities and reduces setup time by allowing tool height adjustments directly through the machine's NC controls.

Automation is seamless with Benzinger's proprietary loading systems, third-party robotic cells, or a bar feeder for uninterrupted bar machining. The entire system is powered by state-of-the-art Siemens or Fanuc controls, offering multiple programming options.

Workspace of the GOFuture BX Mill/Turn Centre

The linear tool design of the Mill/Turn centre offers maximum stability and the shortest chip-to-chip times. In conjunction with the Y-axis, the turning tools are arranged in several rows one above the other. Up to 15 static tools can be set up in this way.

The HSK-32 milling spindle with up to 35,000 rpm offers space for a further 12 tools with its tool changer and rounds off the turning-milling centre.

Turning-milling centre meets robot - the perfect automation concept

5@work CNC Mill/Turn Centre

The 5@work CNC mill/turn centre is a specialised 5-axis machine engineered for the watchmaking and jewellery sectors. Its unique axis configuration provides exceptional freedom for complex tasks like diamond milling, engraving, and automated gemstone setting—capabilities beyond conventional mills. Enhanced by automated loading/unloading, a tool magazine, and turning functions, it is a highly flexible and productive system. Intuitive, parameterised CNC programs simplify operation, while the optional Benzinger Creative CAD-CAM package allows for direct design and seamless conversion into milling programs.

Four C - Diamond Measuring Machine

The FourC is a machine that automates the sorting and measuring of gemstones for use with the 5@work jewellery machines. It precisely measures each stone's dimensions and stores them in a database. The stones are then individually placed in specialized pallets. This data is directly used by the 5@work centre to enable fully automatic gemstone setting. The FourC can also sort stones into customizable size groups for inventory management and offers optional features to distinguish genuine diamonds from simulants like zirconia and to classify a diamond's fluorescence.

What Sets Benzinger Apart?

Extreme Precision & Stability

- High Accuracy Spindles (roundness and runout < 0.5µm).

- Linear guideways and thermally compensated structures for nanometer-level accuracy.

Integrated Hard Turning & Grinding

- Hard turning (up to 72 HRc) replaces grinding, reducing costs and cycle times.

- Mirror finishes (< 3µm) are achievable.

- Dry machining eliminates the requirement for coolant.

- Combined hard turning + grinding for sealing surfaces (e.g., valve seats).

High-Speed Machining Capabilities

- Main and Counter Spindle: 15,000 rpm.

- 5-axis milling spindle: 30,000 rpm (HSK-40).

Deep Hole Drilling

- Gun Drilling with 100 bar coolant pressure.

- L/D ratio > 30 (e.g., medical implants, aerospace components).

Industry 4.0 & Smart Manufacturing

- Benzinger Smart Panel: Real-time tool monitoring, predictive maintenance, and remote access.

- CB-Apps: Digital workflows for setup optimisation, document management.

Rainford Precision’s Unique Value

At Rainford, we’re proud to be the exclusive UK partner for Benzinger, bringing their precision lathes to manufacturers up and down the country. Our team has decades of experience in precision tooling and micro-manufacturing solutions, making us uniquely positioned to support your needs from initial enquiry through to machine delivery, set up training and post-sale service.

We have:

- Technical expertise – We understand the demands of precision engineering across multiple industries and have the technical know-how to advise you on what works best.

- Hands-on support – From test cutting to installation and training, we work closely with our customers to ensure a successful process from start to finish.

- Tooling compatibility – As precision tooling specialists, we can advise you on the optimal combination of machine and tooling accessories to achieve the desired result.

- After-sales care – Our commitment doesn’t end with delivery. We provide ongoing advice and support to keep your operation running smoothly.

Contact us to discover more about how Benzinger Lathes can benefit your business.

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

.png?width=2563&height=2351&name=KERN-Ametek-logo-rot-schwarz%20(1).png)

.png?width=500&height=200&name=PEMtec%20Logo%20(1).png)

.png?width=500&height=200&name=Benzinger%20Logo%20(1).png)

Interested In Our Products?

Get access to our wide range of product brochures

Latest From The Blog

2 min read

Applications Driving Demand For Ultra-Fine Carbide Grades

Jan 8, 2026 by Rainford Precision

5 min read

Electrochemical Production Of Precision Parts At Scerox EDM Technology

Jan 5, 2026 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)