Key Factors That Drive High Precision Machine Tool Performance

The evolution of manufacturing technology has created unprecedented demand for complex, precise components across a vast range of different...

2 min read

Rainford Precision : Jan 23, 2026 10:00:01 AM

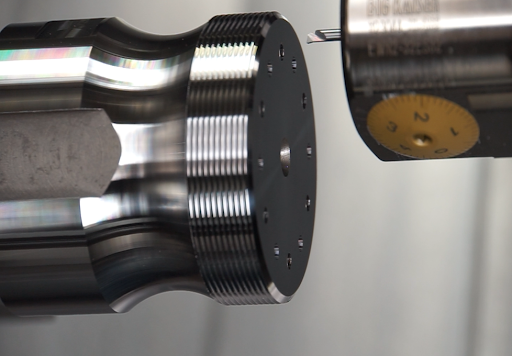

Machining hard materials like tool steel, carbide or fired ceramic whilst maintaining accuracy and structural integrity can be challenging. Without the right boring bar, tool life, surface finish and accuracy can suffer.

If your business machines any of these materials then these issues make for a costly combination leading to wasted time, rework and premature tool replacement due to excessive wear. So how do you choose the right boring bars for the job? Something which repeatedly produces accurate results and enjoys a long tool life?

There’s plenty of choice when it comes to boring bars and manufacturers, and when you’re pricing for a job or a production process it can be tempting to go the for most budget-friendly version. But this could end up costing you more in the long run. Here’s why:

To make sure you having the right boring bar consider the following:

German manufacturer DTS offers CBN (Carbon Boron Nitride) grades, PCD (Polycrystalline Diamond) and even diamond coated boring bars which are well-suited due to their stability at high temperatures and resistance to wear.

DTS offers brazed boring bars down to Ø0.80 mm (Typ BS) and MiniTools with indexable inserts from Ø3.50 mm. Choosing a tool designed specifically for small diameters helps maintain tolerance, surface finish, tool stability and increases tool life.

Make sure you choose a precise tool holding system. DTS’s hydraulic chucks or short, rigid clamping adapters help maintain consistent insert positioning and reduce thermal distortion and runout.

Need help selecting the right boring bar for your specific application? Contact one of our expert team members for a consultation and tool recommendation today!

The evolution of manufacturing technology has created unprecedented demand for complex, precise components across a vast range of different...

For decades, sink Electrical Discharge Machining (sink EDM) has been the undisputed champion for creating complex, precision cavities in hardened...

In the world of fibre optics, where signal integrity hinges on micron-level precision, manufacturers demand machining solutions that deliver flawless...