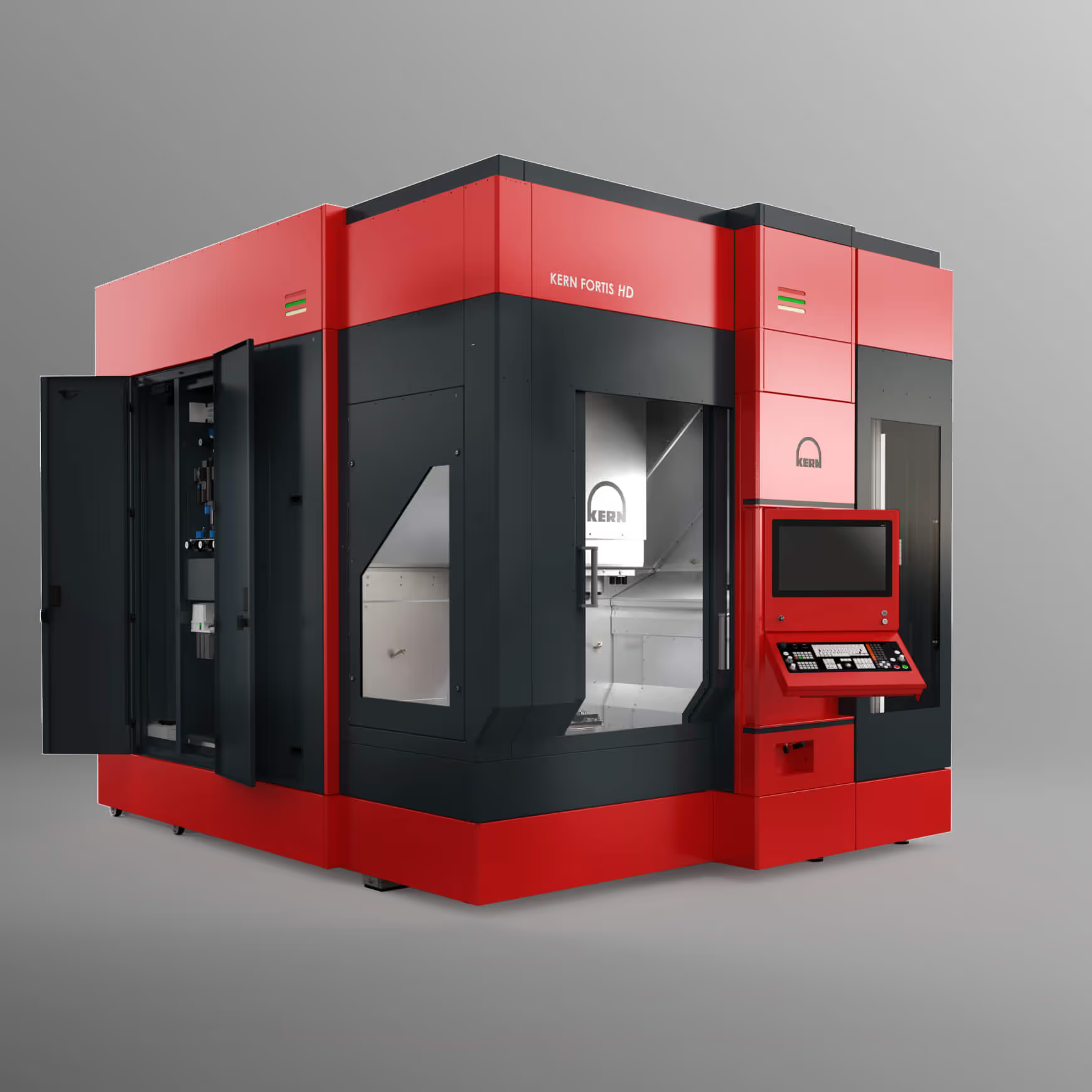

Kern Fortis HD

What Is The Fortis HD Machine?

The Kern Fortis HD is designed to be the most accurate 5-axis machine for reliable high-precision machining in serial production. Parts to be machined range from small to very large, the high productivity, as well as the strong performance in preceding rough machining, make this machine a real asset for high-accuracy machining.

The Fortis HD combines a compact design with an integrated hybrid unit, delivering exceptional stability through the extended Kern temperature management. Only the combination of microgap hydrostatic and lightweight structural aluminium segments with linear direct drives creates the unique, uncompromising synergy in the three-axis structure of the Kern Fortis HD. The implemented tool changer of the Kern Fortis HD is based on the proven Micro Platform and adds new, high-performance features. The integrated 2-axis system offers exceptionally high tool density, providing up to 159 pockets for HSK-A63 tool holders and up to 349 pockets for HSK-E40 tool holders – all within a small footprint.

The Kern Fortis HD brings the highest quality and maximum productivity, powered by the Kern micro-gap hydrostatic, lightweight aluminium architecture and linear direct drives. This Combination results in a machine for producing high-precision parts in series production, which ensures exceptional accuracy under controlled environmental conditions.

X travel: 780 mm

Y travel: 420 mm

Z travel: 450 mm

Kern Microtechnik GmbH, headquartered in Upper Bavaria, Southern Germany, nestled in the scenic foothills of the Alps, with majestic mountains, sparkling rivers, and picturesque lakes, has secured a leading global position in high-precision technology over the past decades. With a strong commitment to innovation, technology, and close customer collaboration, Kern has become a trusted partner for clients worldwide, helping them achieve ambitious goals across various industries such as medical, aerospace, watchmaking, defense, semiconductors, and more. A shared vision of sustainable, cross-generational development drives our work. Our innovative spirit, adaptability, and, most importantly, our outstanding team, are the keys to our corporate strength and resilience through challenging times.

Why Choose Rainford?

Sole UK agents for Kern

Highly knowledgeable Kern specialists

Can advise on products to suit your business needs and fit your budget

Great communication and first-class customer service

ISO 9001 certified

Download KERN Fortis HD Brochure

Unrivalled precision for micro-accurate series production

The Kern Fortis HD is designed for applications that demand the highest precision and surface quality, as well as high cutting performance.

- Maximum machine stability thanks to extended KERN temperature management.

- Highly dynamic acceleration and maximum travel speed thanks to a transmission-free drive system.

- Highest possible quality and freedom from wear thanks to innovative, newly dimensioned KERN micro-gap hydrostatics.

- Maximum accuracy with minimum warm-up time thanks to topology-optimised aluminium axes.

- Integrated tool management system with exceptionally high tool density and minimal footprint.

- Multi-shift operation without operators and with an integrated tool-changer for up to 210 tools and max. 60 workpieces.

- Certified interfaces for additional accessories and automation systems.

Kern Fortis Brochure

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

.png?width=500&height=200&name=PEMtec%20Logo%20(1).png)

.png?width=500&height=200&name=Benzinger%20Logo%20(1).png)

Interested In Our Products?

GET ACCESS TO OUR WIDE RANGE OF PRODUCT BROCHURES

Latest From The Blog

2 min read

Applications Driving Demand For Ultra-Fine Carbide Grades

Jan 8, 2026 by Rainford Precision

5 min read

Electrochemical Production Of Precision Parts At Scerox EDM Technology

Jan 5, 2026 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)