Scerox Erodiertechnik GmbH specialises in the ultra-precise machining of metal components. With accuracies down to the sub-micrometer range, the company sets standards in EDM technology.

In order to meet increasing demands for shorter delivery times and higher quantities, Scerox has been expanding its portfolio since 2023 to include the PECM process – a technology that ideally combines precision and productivity.

Typical applications include turbine blades, gears, injectors, medical tools or implants, as well as components that need to be microstructured. Image: PEMTec

Shortcut

- Task: Customer request for shorter delivery times and higher quantities with the highest precision at the same time.

- Solution: Use of the PECM process (Pulsed Electro-Chemical Machining) with a PEMTec PEM 800 S

- Benefits: Very short machining times; burr-free, high-gloss surfaces; high repeatability; economical for medium and large series.

"We specialise in the production of drawing parts with accuracies of up to 0.5 μm," says toolmaker Christian Stumpf, Managing Partner and Sales Manager of Scerox Erodiertechnik GmbH in Redwitz a. d. Rodach. With currently 130 employees, the company operates over 30 wire EDM machines and numerous die-sinking EDM machines. Thanks to end-to-end automation, the systems run around the clock in 24/7 operation – an essential factor in remaining competitive in the market.

An extensive range of machinery is available for further machining tasks: universal milling machines, HSC microcentres, internal and external cylindrical grinding machines and profile grinding technology. The equipment is supplemented by modern precision measurement technology for quality assurance and software solutions for the conversion of CAD data into CAM programs. In addition to steel, stainless steel and aluminum, the material portfolio also includes sophisticated materials such as tungsten, lanthanum or high-temperature alloys, for example for turbines.

Its customers include mainly high-tech companies from the fields of medical technology, aerospace, defense technology and mechanical engineering, but also the automotive industry.

The PEM 800 S used by Scerox is the flagship of the PEMTec machine series. Their usable working area height is between 375 and 545 mm.

"With the PECM process, we can offer our customers not only the highest precision, but also significantly shorter machining times – a decisive advantage in an increasingly competitive market."

Christian Stumpf - Managing Partner and Sales Manager, Scerox Erodiertechnik GmbH

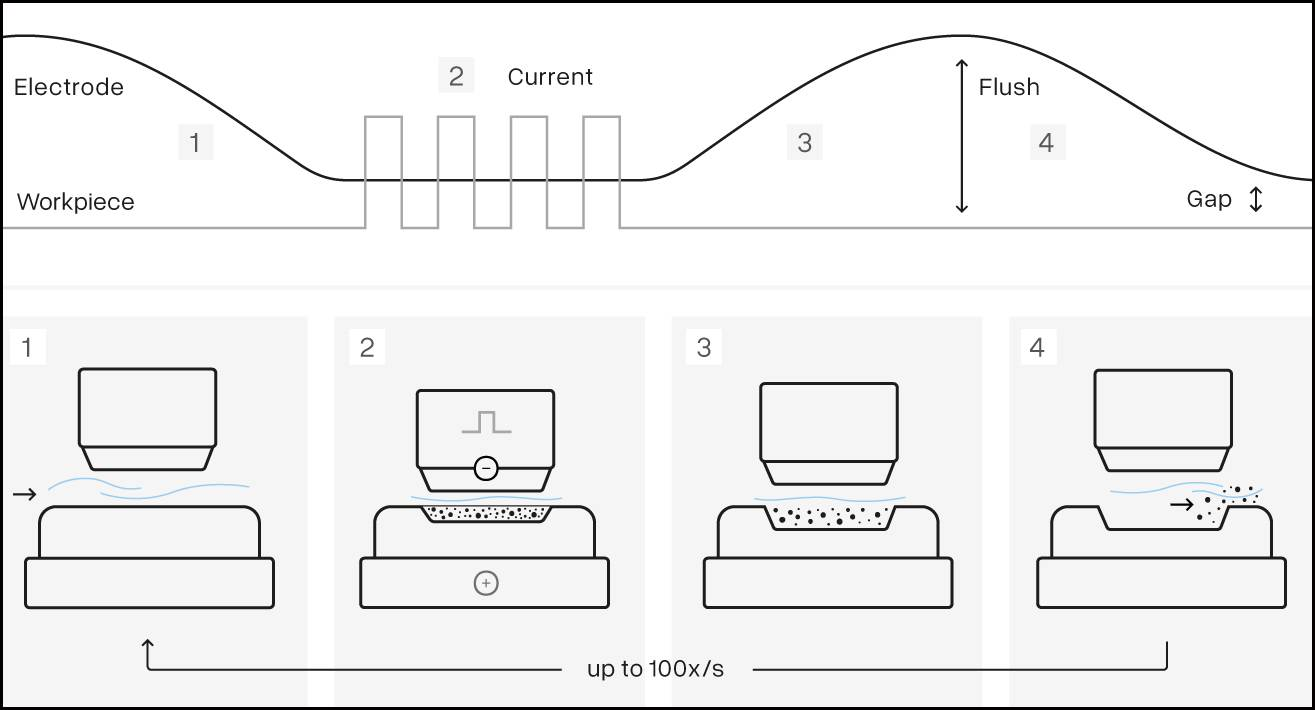

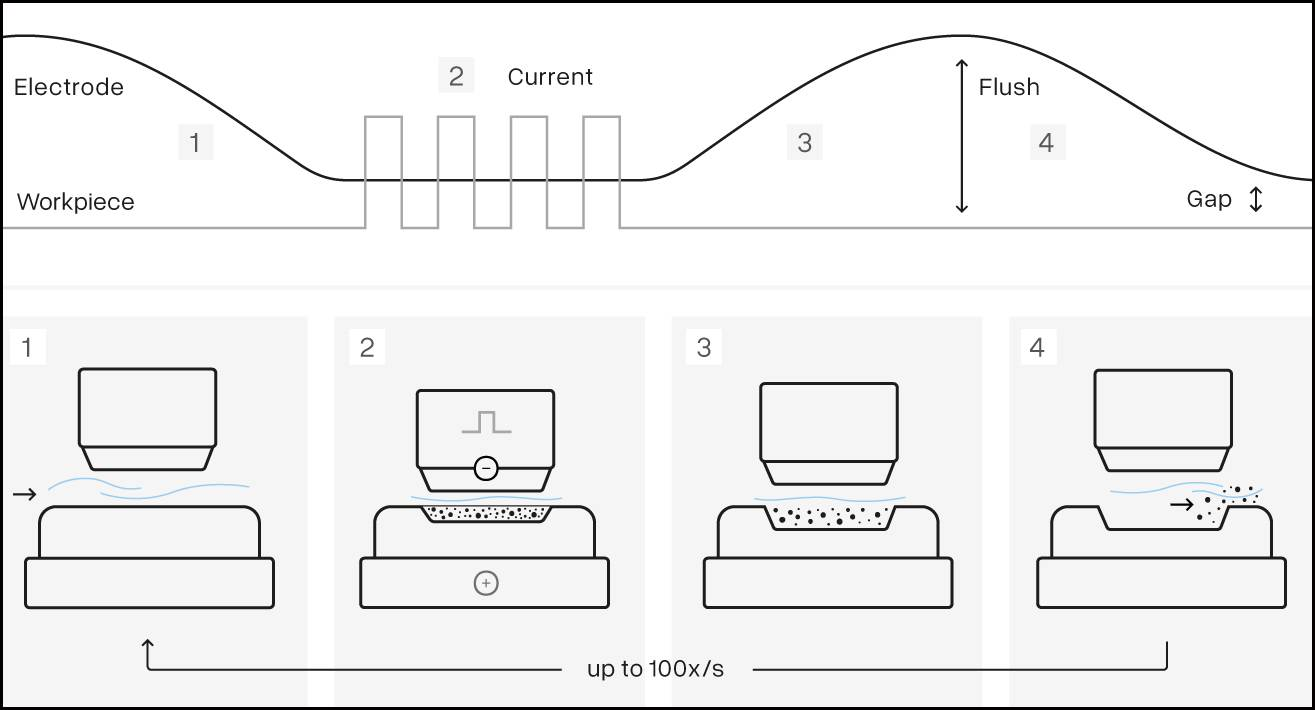

The PECM Process

"The EDM techniques are very precise, but their productivity is limited," recalls master toolmaker Hermann Stumpf, managing partner and production manager of the company. The transit times are usually in the range of hours or even days. Customer requests for shorter deadlines or higher quantities could therefore not always be met. In his search for alternatives, he came across the PECM process (Pulsed Electro-Chemical Machining), which has certain parallels to die-sinking EDM: Here, too, the processing is carried out via electric current in a water bath.

In contrast, however, PECM uses salt water instead of deionized water. The tool is a negative mold of the desired component and is made of tool steel instead of graphite or copper. The ablation is carried out purely electrochemically by superficial dissolution of the workpiece connected as a negative pole. Thanks to high currents, machining is very fast. Typical working speeds are 0.5 to 2.0 mm/min for roughing, 0.1 to 0.5 mm/min for finishing and < 30 seconds for polishing. Machining times for the range of parts at Scerox are typically between 30 and 120 seconds. The dimensions are usually below 300 × 300 × 150 mm, but the system can also accommodate larger parts.

In the non-contact, cold PECM process, the workpiece is dissolved without damage to the crystal structure, and the burr- and groove-free surface appears smooth and shiny. This is particularly desirable, for example, for components such as turbine blades or guide vanes that are to be used in flowing media, but also for optical or medical applications.

The entire system consists of the PEM 800 S processing unit, the control console, the PEM Control control system (right, front control cabinet), the PEM Power power unit behind it and the PEM Aqua electrolyte preparation unit at the very rear (Image: mrazek)

Wide Range Of Materials And Parts

"With the PECM process, we can process almost the same range of parts as we previously did with spark EDM," says C. Stumpf happily. Typical applications include turbine blades, gears, injectors, medical tools or implants, as well as components that need to be microstructured. It is also suitable for miniature components for industries such as watches, sensors or optics. The tolerances are in the range of ± 2 to 5 μm (for very complex geometries possibly ± 10 μm) with repeatable accuracies < 1.5 μm. The smooth and burr-free components are high-gloss to almost polished with Ra values of 0.05 to 0.20 μm.

As a result, there is little close-up work, and often grinding and polishing work can be completely omitted because simple cleaning is sufficient. Depending on the electrode shape, radii from 0.01 mm are possible. Micro holes can be created from about 0.01 mm Ø. Almost all industrial metals can be processed. These include low- and high-alloy steels and the usual non-ferrous metals, but also nickel-based alloys and high-temperature materials such as Inconel. The same applies to exotics such as titanium, cobalt, molybdenum and hard metals.

"The PECM process opens up completely new possibilities for us in production: burr-free surfaces, extremely short machining times and repeatability that meets even the highest demands."

Hermann Stumpf - Managing Partner and Production Manager, Scerox Erodiertechnik GmbH

Ideally Suited For Series Production

"The PECM process is ideal for series production," explains Hermann Stumpf. Although the tooling costs for steel electrodes are higher than for the usual copper or graphite electrodes in die-sinking EDM, they do not wear out and can be used virtually indefinitely. This guarantees consistent quality of all workpieces. Thanks to the short processing times, the process is highly productive – especially economical for medium to large series of approx. 100 pieces or more. However, smaller quantities or prototypes can also be realized at the customer's request, provided that the effort for cathode production is justified.

Experience With Operation And Service

"We received our system in March 2023," recalls H. Stumpf. The experience with the manufacturer PEMTec has been consistently positive, the system runs very reliably and the support during training and later in the event of problems is good. The operability of the machine is good, but the employees need a comparatively long training period due to the special nature of the technology. This has less to do with the machine itself than with the widely differing approaches to the design of the tool and the electrode.

The high tool costs also took some getting used to, especially for small quantities. "On balance, we are so satisfied with the technology and the supplier PEMTec that we are considering the procurement of two more systems of this type despite the subdued overall economic situation," C. Stumpf sums up.

User: Scerox

Scerox Erodiertechnik GmbH in Redwitz a. d. Rodach is a leading provider of state-of-the-art precision technologies. The company offers a wide range of EDM processes, high-precision grinding, milling and turning-milling to innovative processes such as PECM and cleanroom production. With 120 employees, strong regional roots and a clear commitment to innovation, training and community, Scerox combines the highest quality with lived values.

Scerox Erodiertechnik GmbH & Co. KG. Dr.-Ludwig-Vierling-Straße 1296257 Redwitz a.d.Rodach - https://www.scerox.de

PEMTec PEM 800

The PEM 800 is the further development of the PEM 600. Here everything is a little bigger; the machining space, the electrode weight, the generator, with up to 12,000 amperes and thus at the same time the components to be manufactured. In addition, the PEM 800 also offers a different axis guide. The doors can also be opened from the side.

Explore PECM Technology with Rainford Precision

As the sole authorised agent for PEMTec in the UK and Ireland, Rainford Precision can help you evaluate whether PECM is right for your application. With over 30 years of experience in high-precision machining solutions, our team offers consultancy, machine supply, and ongoing technical support.

Whether you're looking to improve productivity, reduce secondary operations, or achieve superior surface finishes on complex geometries, we're here to help you find the optimal solution.

Ready to discuss your requirements? Speak with our technical team or learn more about the PEMTec PECM machine range.

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)