Carl Benzinger Lathes: The Precision Powerhouse for Fibre Optic Connector Manufacturing

In the world of fibre optics, where signal integrity hinges on micron-level precision, manufacturers demand machining solutions that deliver flawless...

3 min read

Rainford Precision : Oct 30, 2025 11:30:00 AM

When precision and speed matter, choosing the right turning centre makes all the difference. In precision CNC machining, high-speed spindles determine the performance, accuracy, and efficiency of turning operations.

Benzinger turning centres, represented in the UK and Irish markets by Rainford Precision, integrate advanced high-speed spindle technology that sets them apart from competitors. They deliver exceptional build quality, cutting-edge precision, and unmatched reliability for demanding applications.

High-speed spindles on Benzinger turning centres deliver three core advantages: reduced machining time through spindle speeds up to 16,000 RPM, superior surface finish with minimal vibration and runout below two microns, and enhanced multi-tasking capabilities including integrated milling and drilling operations. This combination of speed, accuracy, and versatility positions Benzinger CNC lathes as the preferred choice for manufacturers requiring exceptional precision.

High-speed spindles on Benzinger turning centres allow for significantly faster cutting speeds, reducing cycle times and increasing throughput. The productivity benefits include:

Reduced Machining Time: Higher spindle speeds enable faster material removal rates, particularly in fine finishing operations. The main spindle operates at speeds up to 16,000 RPM, whilst the integrated milling spindle achieves up to 30,000 RPM with HSK40 connection capability.

Efficient Chip Evacuation: The increased rotational speed improves chip formation and evacuation, minimising downtime for chip clearing. This can be coupled with coolant pressure of up to 100 bar, ensuring optimal chip management during high-speed operations.

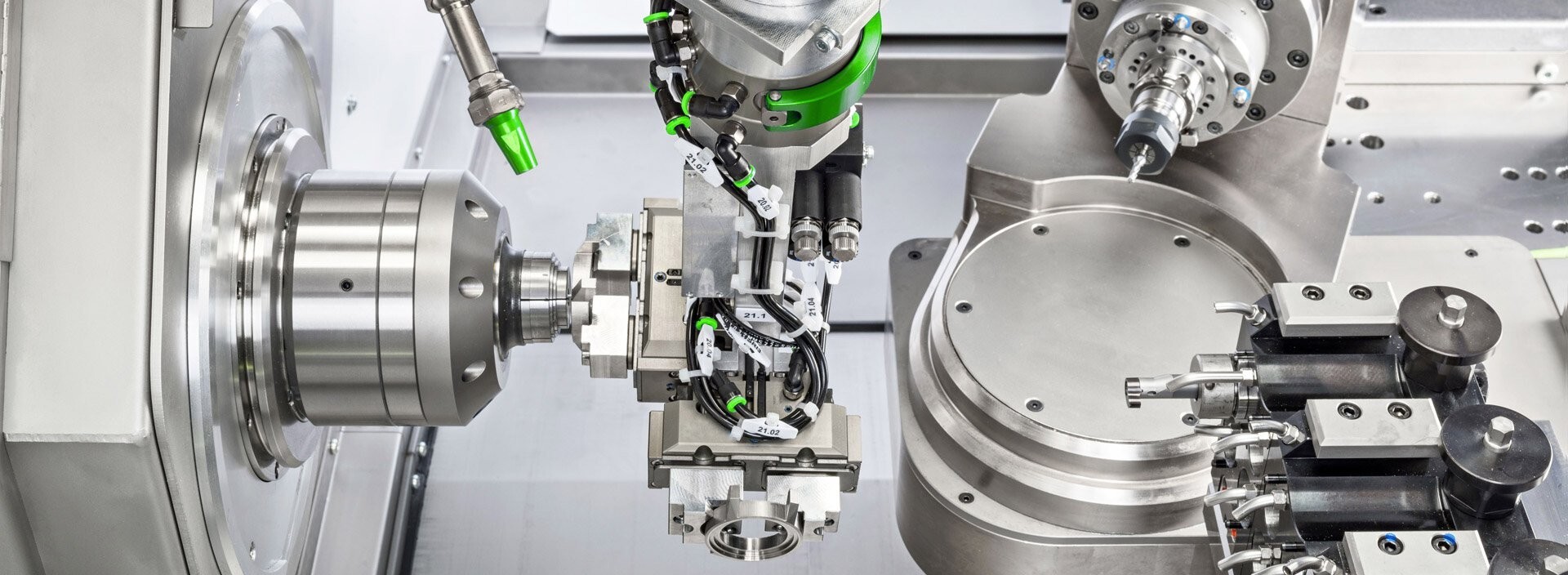

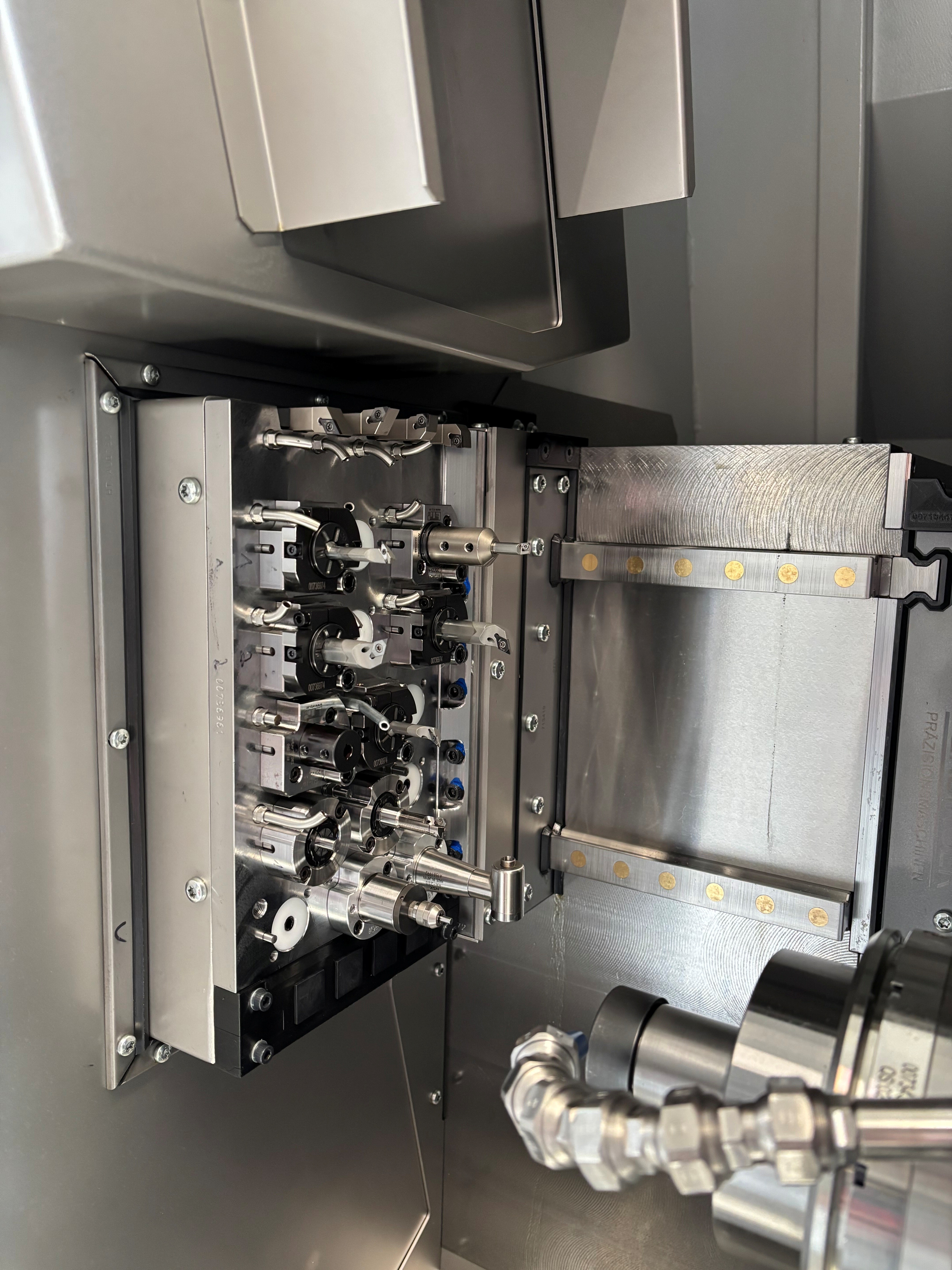

Multi-Tasking Capabilities: Benzinger's highly flexible modular design characteristics can be adapted to suit any application. High-speed spindles support live tooling, allowing for milling, drilling, and precision turning in a single setup, further boosting productivity and reducing handling time.

The precision engineering of Benzinger's high-speed spindles ensures exceptional accuracy and surface quality across all turning operations:

Minimal Vibration and Runout: High-quality bearings combined with rigid spindle design and construction reduce vibration, ensuring minimal runout to less than two microns. This level of precision is critical for industries requiring tight tolerances.

Improved Surface Finish: Faster spindle speeds and higher rigidity produce superior surface finishes, reducing or eliminating the need for secondary finishing operations. This translates to cost savings and faster production cycles.

Thermal Stability: Advanced design accounts for uniform thermal expansion, coupled with mechanisms that minimise the centre height from the machine bed. These features minimise thermal expansion effects and maintain both machine and spindle accuracy even during prolonged high-speed operation.

Benzinger CNC lathes, available in the UK and Ireland through Rainford Precision, stand out in the precision machining market due to their specialised design and engineering excellence:

Customisable Spindle Options: Benzinger offers tailored spindle configurations for specific applications, including ultra-high-speed machining and hard turning operations. This flexibility ensures manufacturers can optimise their setup for their exact requirements.

Integration with Automation: These turning centres can be integrated with robotic loading systems suited to the specific requirements of each application, making them ideal for high-volume precision manufacturing environments.

Niche Applications: Benzinger machines are favoured in industries requiring extreme precision, such as medical device manufacturing, aerospace component production, and optical component manufacturing. The combination of speed and accuracy makes them particularly suitable for complex, high-value parts.

The ability of Benzinger turning centres to sustain high cutting speeds without compromising accuracy is rooted in their superior construction:

Rigid Machine Structure: High-grade materials and reinforced bed designs, coupled with enhanced machine architecture, account for both rigidity and uniformity of thermal growth and load during machining. This minimises deflection under high-speed loads and ensures consistent performance.

Advanced Spindle Bearings: Premium quality bearings ensure long-lasting performance with minimal wear, even under the demanding conditions of continuous high-speed operation.

Precision Balancing: The spindles are dynamically balanced both front and rear to achieve a higher degree of balance that eliminates harmonics which could affect machining quality. This process has been developed by Benzinger and is yet another factor which sets their machines apart from the competition.

The integration of high-speed spindle technology in Benzinger turning centres delivers unmatched productivity, precision, and surface finish, making them the preferred choice for industries demanding the highest levels of accuracy.

Their robust build quality, combined with innovative machine design and advanced spindle technology, ensures reliable performance even at extreme cutting speeds. Benzinger CNC lathes maintain a unique and competitive position in the precision machining market, offering precision turning solutions that few competitors can match.

For manufacturers in the UK and Ireland seeking to optimise efficiency and quality in high-precision turning operations, Rainford Precision provides expert support and access to Benzinger's cutting-edge high-speed spindle technology. Contact our team today to discover how Benzinger turning centres can transform your precision machining capabilities.

In the world of fibre optics, where signal integrity hinges on micron-level precision, manufacturers demand machining solutions that deliver flawless...

Scerox Erodiertechnik GmbH specialises in the ultra-precise machining of metal components. With accuracies down to the sub-micrometer range, the...

Rainford Precision Machines Limited, the UK-based leader in high-precision cutting tools and machining solutions, has established itself as a trusted...