High-Speed Spindle Technology On Benzinger Turning Centres

When precision and speed matter, choosing the right turning centre makes all the difference. In precision CNC machining, high-speed spindles...

2 min read

Rainford Precision : Oct 10, 2025 12:00:00 PM

In the world of fibre optics, where signal integrity hinges on micron-level precision, manufacturers demand machining solutions that deliver flawless accuracy, repeatability, and efficiency. Carl Benzinger lathes, distributed in the UK and Ireland by Rainford Precision Machines Limited, stand at the forefront of this high-precision revolution.

Comprising all the precision associated with high-quality German Engineering, Benzinger lathes excel in producing fibre optic connectors —critical components requiring sub-micron tolerances and mirror-like surface finishes.

With a firm focus on achieving extreme accuracy by incorporating tried and tested modularity, Benzinger lathes are the ideal choice for machining fibre optic connectors, supported by real-world machining methodologies. The unique advantages of the Benzinger approach means it is possible to achieve complete "parts off in one process" from bar.

Fibre optic connectors rely on ferrules to align optical fibres with near-perfect accuracy. Even a 1µm deviation can cause:

To meet these demands, manufacturers require:

Benzinger lathes are engineered for high precision and high speed utilising modular systems with main spindle speeds of up to 15,000rpm, the focus is on providing the right machine for the job to give the right solution and the best possible outcome.

Case Study Example:

A leading European fibre optic manufacturer reduced ferrule rejection rates by 40% after switching to a Benzinger lathe, thanks to its ability to hold ±1µm tolerances consistently, due to in process measuring methodology.

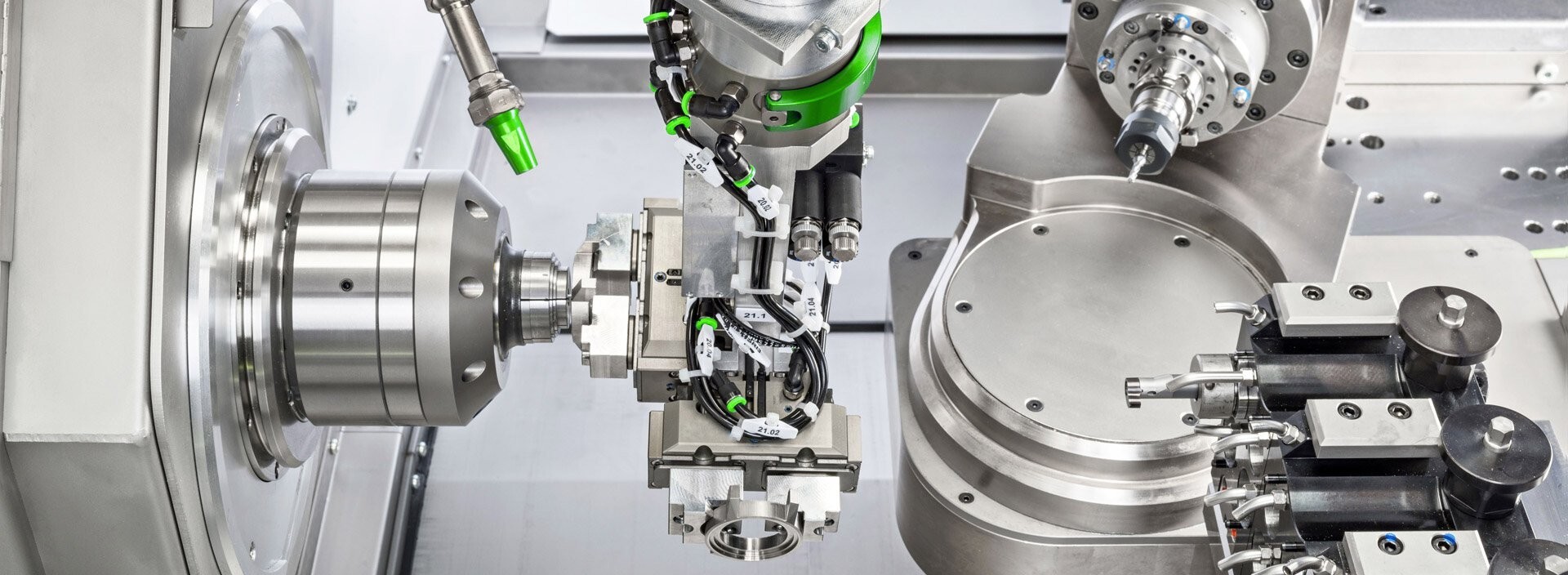

Shown here, the critical tools are measured in process to give added micron level repeatability. This system from Blum is incorporated in the design of the twin spindle twin turret GoFuture B6.

Continuous production is achieved by Benzinger machines due to all critically tolerance features being carried out in one clamping:

Result: Lower cost per part, reduced scrap, and higher consistency.

Fibre connectors require < 0.1µm finishes in some cases, to minimise light scattering. Benzinger lathes achieve this due:

With their uniquely applications driven approach and unsurpassed quality, Benzinger meets the high demand of this industry sector head on. Benzinger lathes are trusted by:

✅ Ferrule manufacturers

✅ Connector body producers

✅ Defence & telecom suppliers (high-reliability optical components).

Example: High-Volume MTP Connector Production

A global telecom firm adopted Benzinger lathes for MTP/MPO connector ferrules, achieving:

For fibre optic connector manufacturers, Carl Benzinger lathes offer:

Rainford Precision Machines Limited provides local UK & Ireland support, ensuring seamless integration and optimisation throughout.

With the fibre optics market growing at 9% annually (2024-2030), manufacturers must invest in high-precision, high-efficiency machining. Carl Benzinger lathes are not just machines, they are strategic partners in achieving zero-defect, high-yield production.

When precision and speed matter, choosing the right turning centre makes all the difference. In precision CNC machining, high-speed spindles...

In the world of precision engineering, partnerships are not just about business—they are about shared values, complementary expertise, and a...

Rainford Precision Machines Limited, the UK-based leader in high-precision cutting tools and machining solutions, has established itself as a trusted...