High-Precision CNC Machining For Medical Industry

When visiting a doctor, the hospital or dentist, few people stop to consider where the medical instruments or components used in their treatment originate. Yet, it is CNC machining for the medical industry that makes the precise manufacturing of these parts – and your successful treatments – possible.

At Rainford Precision we understand the highly specialised nature of CNC machining medical devices and the next-level precision that’s required. Whether it’s dental implants, surgical tools or hip replacements, we can supply the right tools and CNC solutions to enable accurate manufacture down to micron level.

The Role Of High-Precision CNC Machining In the Medical Industry

Manufacturing in the medical industry is highly specialised and challenging – not only do parts produced have to be exceptionally accurate, but they must also be made from materials compatible with the human body, suitable for sterilisation and which minimise bacterial contamination and corrosion. It’s why manufacturers adhere to ISO13485, a voluntary standard that specifies quality management systems for medical devices, and other regulatory standards which are non-negotiable.

CNC machining for medical purposes is essential because it minimises defects, ensures repeatable precision and enhances the reliability of medical devices. It also means parts made from difficult-to-machine materials like cobalt chrome, titanium, stainless steel, ceramics and resistant plastics can be manufactured with an exceptionally high level of accuracy.

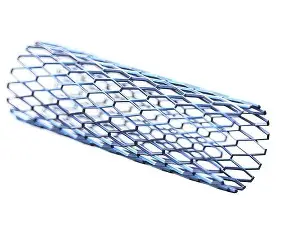

Materials such as ceramics, used for things like dental implants, dental cleaning tools and prosthetics, are notoriously difficult to machine with a high risk of cracks and fractures. This is combined with growing customer demand for extremely tight tolerances. Without precision CNC centres such accuracy would not be achievable.

How Our Machines Are Helping Revolutionise Medical Manufacturing

Rainford Precision Machines Limited is a key player in the medical sector across the UK and Ireland, providing ultra-high-precision machining solutions tailored for medical device manufacturing. The company’s advanced machine tool portfolio includes Kern’s 5-axis machining centres, renowned for ±1µm precision, and Benzinger’s high-accuracy turning centres, which enhance productivity and flexibility in medical component production. Rainford also introduces PEMTec’s precision electrochemical machining (PECM) technology, enabling sub-micron accuracy and superior surface finishes without thermal distortion ideal for delicate medical implants. Additionally, Finepart’s micro abrasive waterjet systems offer non-thermal cutting with ±2.5µm positional accuracy, critical for heat-sensitive materials like Nitinol widely utilised in medical applications. The newly added Innolite range brings diamond turning capabilities to optical and medical mould tool manufacturing. Through these technologies, Rainford empowers medical manufacturers with cutting-edge precision, efficiency, and innovation.

.png?width=1200&length=1200&name=_Innolite%20IL1600%20(1).png)

Why Choose Rainford Precision?

At Rainford we understand the need for accuracy and precision is paramount within the medical industry. We are the sole supplier of Kern, Benzinger, Innolite and Finepart machines in the UK which means we are uniquely positioned to advise on the best and most effective options for the manufacture of different medical components.

- We have more than 30 years’ experience supplying machining centres and precision tooling parts for the medical manufacturing industry

- We supply a wide range of micro-cutting tools designed for high precision, durability and performance

- We offer a customer-centric approach providing bespoke recommendations, technical support and personalised service to meet the unique needs of every medical manufacturer

Discover how Rainford Precision supports medical manufacturing and can help your business.

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

Book A Consultation

Revolutionise your machine drilling operations today! Take the first step by booking a consultation and a member of our seasoned team will analyse and optimise your processes, recommending cutting-edge technologies for enhanced precision and productivity.

Interested In Our Products?

GET ACCESS TO OUR WIDE RANGE OF PRODUCT BROCHURES

.png?width=2563&height=2351&name=KERN-Ametek-logo-rot-schwarz%20(1).png)

.png?width=500&height=200&name=PEMtec%20Logo%20(1).png)

.png?width=500&height=200&name=Benzinger%20Logo%20(1).png)

Latest From The Blog

2 min read

Applications Driving Demand For Ultra-Fine Carbide Grades

Jan 8, 2026 by Rainford Precision

5 min read

Electrochemical Production Of Precision Parts At Scerox EDM Technology

Jan 5, 2026 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)