Electrochemical Production Of Precision Parts At Scerox EDM Technology

Scerox Erodiertechnik GmbH specialises in the ultra-precise machining of metal components. With accuracies down to the sub-micrometer range, the...

2 min read

Rainford Precision : Aug 26, 2025 12:00:00 PM

The New Frontier In Precision Just Got A Little Closer...

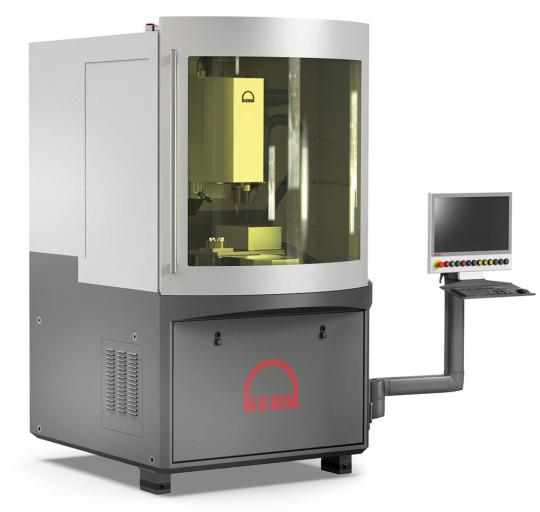

The Kern Femto E3 and E5 Laser Machining Centres represent the pinnacle of precision engineering, combining femtosecond laser technology with advanced automation and adaptive machining capabilities. These machines are designed to meet the most demanding requirements of modern manufacturing, offering unparalleled accuracy, versatility, and efficiency. With both 3-axis (E3) and 5-axis (E5) configurations, they cater to a wide range of applications, from micro-milling to surface texturing, making them indispensable tools for industries pushing the boundaries of precision.

One of the standout features of the Kern Femto series is its integrated measurement system, which ensures consistent precision throughout the machining process. The system continuously monitors the focus position, laser beam power, and X-Y positioning across the entire scan field. Any deviations in spot position or laser power are detected and calibrated directly on the workpiece, ensuring a stable and reliable process. This automated measurement capability eliminates manual adjustments, reduces errors, and maintains the highest levels of accuracy, even during complex operations.

The Femto series incorporates adaptive machining, a ground-breaking feature that automatically measures the actual material abrasion during the machining process. The system compares the measured results with the target contour and adjusts the machining parameters in real time. This ensures automatic compensation for any deviations, enabling the production of components with the tiniest shape tolerances. Adaptive machining is particularly beneficial for applications requiring extreme precision, such as medical implants or microelectronic components, where even the slightest error can be critical.

The Kern Femto E3 and E5 excel in laser micro-milling, a process that uses ultrashort pulse lasers to machine intricate structures into nearly any material. This technology is especially effective for hard materials like cemented tungsten carbide, which are difficult to process using conventional methods. The femtosecond laser removes extremely thin layers of material without generating heat, preserving the integrity of the workpiece and eliminating the need for post-processing.

For example, machining a carbide press tool insert takes just 2 hours with the Femto series, compared to significantly longer times with traditional EDM methods. Additionally, the process requires no consumables or electrodes, reducing production costs and simplifying operations.

The Femto series also introduces advanced laser surface texturing capabilities, enabling the creation of fine micron-sized features with high depth resolution. This technology allows manufacturers to alter the functional properties of surfaces, such as reducing friction or changing optical characteristics.

Textures can be applied directly to parts or to tools like injection moulds, with the functional properties transferred to the final product during the moulding process. The 5-axis capability of the Femto E5 further enhances this feature, allowing for the application of textures on complex curved surfaces with exceptional precision.

The Kern Femto E3 and E5 are not only precise but also environmentally friendly. They operate with low energy consumption, require no coolants or lubricants, and produce minimal waste. The absence of chip removal and low noise levels further contribute to their sustainability, making them ideal for modern, eco-conscious manufacturing environments.

The versatility of the Kern Femto series makes it suitable for a wide range of industries, including:

The Kern Femto E3 and E5 Laser Machining Centres are redefining precision manufacturing with their advanced automation, adaptive machining, and versatile capabilities. From laser micro-milling to surface texturing, these machines deliver unmatched accuracy and efficiency, making them indispensable for industries that demand the highest levels of precision.

Whether producing intricate medical devices or robust industrial tools, the Femto series sets a new standard for innovation and performance in modern manufacturing.

Scerox Erodiertechnik GmbH specialises in the ultra-precise machining of metal components. With accuracies down to the sub-micrometer range, the...

Recently our partner, Kern Microtechnik, were in the spotlight regarding how much their Five-Axis Evo machine helped Toronto based company, Integral...

The precision engineering landscape in the UK and Ireland is set for a transformative leap forward with the newly announced partnership between PEMTec