Why Custom Cutting Tools Matter In Precision Engineering

Accuracy is synonymous with precision engineering and while standard tools can deliver acceptable results, they often fall short when absolute...

2 min read

Rainford Precision : Oct 20, 2025 12:00:00 PM

When machining operations require consistent holes within tight tolerances, manufacturers face a critical choice between reaming and boring. Whilst both processes can achieve precision results, specific applications clearly favour reaming over traditional boring methods.

Precision reamers, particularly solid carbide variants, offer distinct advantages in tolerance control, production efficiency, and long-term consistency. Understanding when to deploy each process can significantly impact production outcomes and cost-per-part calculations.

Boring employs a single-point cutting tool to enlarge and refine existing holes, offering flexibility to adjust diameter incrementally and correct geometric imperfections such as poor roundness or straightness. This adjustability makes boring ideal for custom sizing, stepped bores, and large-diameter applications.

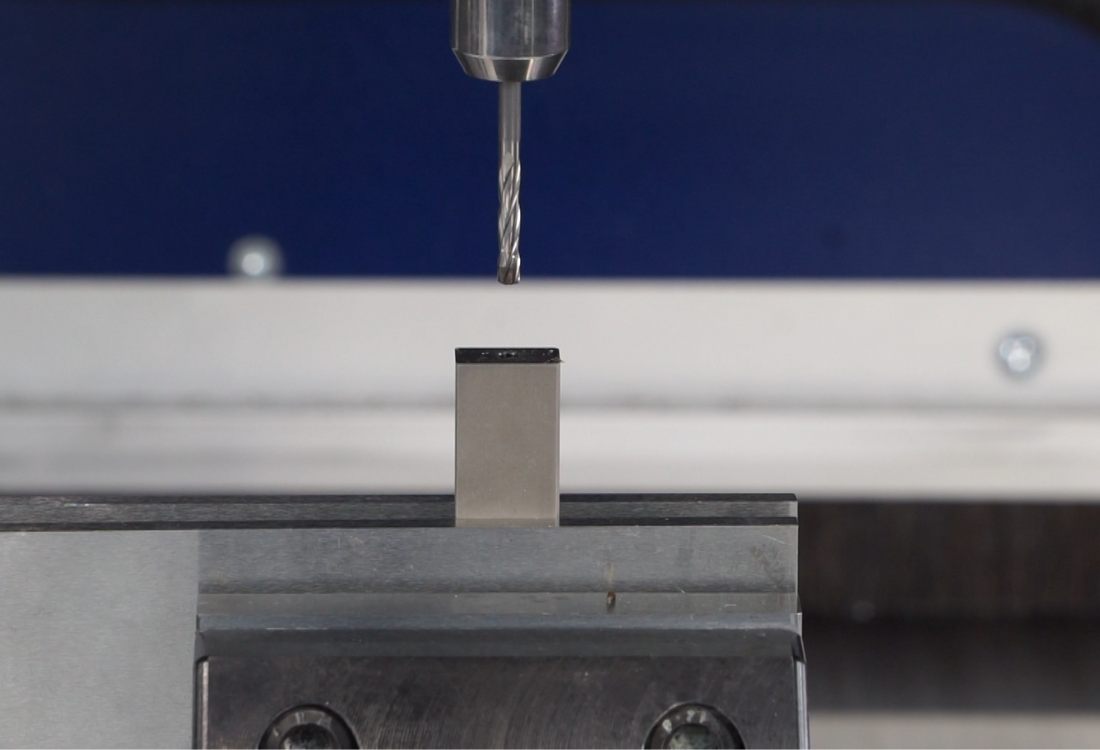

Reaming uses a multi-fluted cutting tool designed to remove minimal material whilst achieving precise dimensional control and superior surface finish. The process creates consistent hole sizes with minimal setup requirements, making it optimal for high-volume production of identical components.

The most compelling reason manufacturers choose precision reamers lies in their exceptional tolerance capabilities. Quality reamers consistently maintain tolerances within ±5 µ, making them ideal for achieving H7 tolerance classes (typically +25/0 µ for holes in the 6-30mm range) required in precision assemblies. Tolerances down to +/- 1µ are achievable for special requirements.

This tolerance control stems from the reamer's multi-fluted design, which distributes cutting forces evenly and minimises tool deflection. In contrast, boring tools, despite their adjustability, are more susceptible to variation due to insert wear, machine dynamics, and the inherent deflection characteristics of single-point tools.

For applications where dimensional consistency defines quality, such as bearing seats, pin holes, or hydraulic components, reaming delivers superior repeatability across production runs.

Reamers excel in high-volume manufacturing environments through their ability to complete hole finishing in a single pass. This contrasts with boring operations, which often require multiple passes and frequent dimensional verification to maintain accuracy.

The efficiency advantage becomes particularly pronounced in automated production lines where cycle time directly impacts profitability. Whilst boring requires complex toolpath programming and iterative adjustments, reaming follows a straightforward process with predictable outcomes.

Additionally, the reduced setup complexity of reaming operations (requiring no insert selection, minimal toolpath programming, and fewer operator variables) contributes to faster changeovers and reduced downtime between production runs.

Simpler To Set Up, Easier To Control

One of the biggest advantages reamers have over boring bars is their ease of setup – in fact they require minimal setup because there’s no insert selection, limited toolpath complexity and fewer operator variables.

Borers, on the other hand, often require multiple adjustments, advanced CNC programming and frequent probing to maintain tight tolerances.

While boring bars are effective in producing consistent holes and tight tolerances, the smaller you go the more the chances of imperfections increase. This is particularly true of diameters <10 mm. At this level or below they become increasingly fragile, simultaneously becoming more susceptible to vibration and deflection, especially at high L/D ratios.

Solid carbide reamers, on the other hand, offer excellent structural rigidity and superior performance in miniature or deep-hole machining. They are more stable and predictable, making them the preferred tool for high-precision small-hole finishing.

Tool life and consistency are important factors when you have a long production run – the last thing you want is to be replacing tools too frequently because this can impact production, quality and even necessitate parts being re-machined.

Carbide reamers, especially those made from ultra-fine grain carbide, wear gradually and predictably. This makes it easier to manage maintenance schedules and avoid sudden shifts in performance. By contrast, boring tools with replaceable inserts often show greater diameter drift over time, requiring frequent wear adjustments and offsets to maintain accuracy.

Boring tools certainly have their place in machining, but precision reamers excel in speed, repeatability and tight tolerance performance. If you’re looking to optimise quality in high-volume precision machining, then reamers represent a reliable and effective option.

Discover how reamers can deliver tighter tolerances and better surface finishes in your high-spec machining projects. Speak to our tooling experts today for tailored recommendations!

Accuracy is synonymous with precision engineering and while standard tools can deliver acceptable results, they often fall short when absolute...

Watchmaking is a craft that demands unparalleled precision. Historically, master watchmakers would dedicate days, even weeks, to handcrafting every...

Satellite manufacturing isn’t for the faint hearted – not only does it require pinpoint level accuracy, but components need high-performance thermal...