Revolutionising Stent Manufacturing

Finepart’s Cutting-Edge Micro Abrasive Waterjet Technology, Supplied by Rainford Precision

2 min read

Rainford Precision : Jan 22, 2024 11:00:00 AM

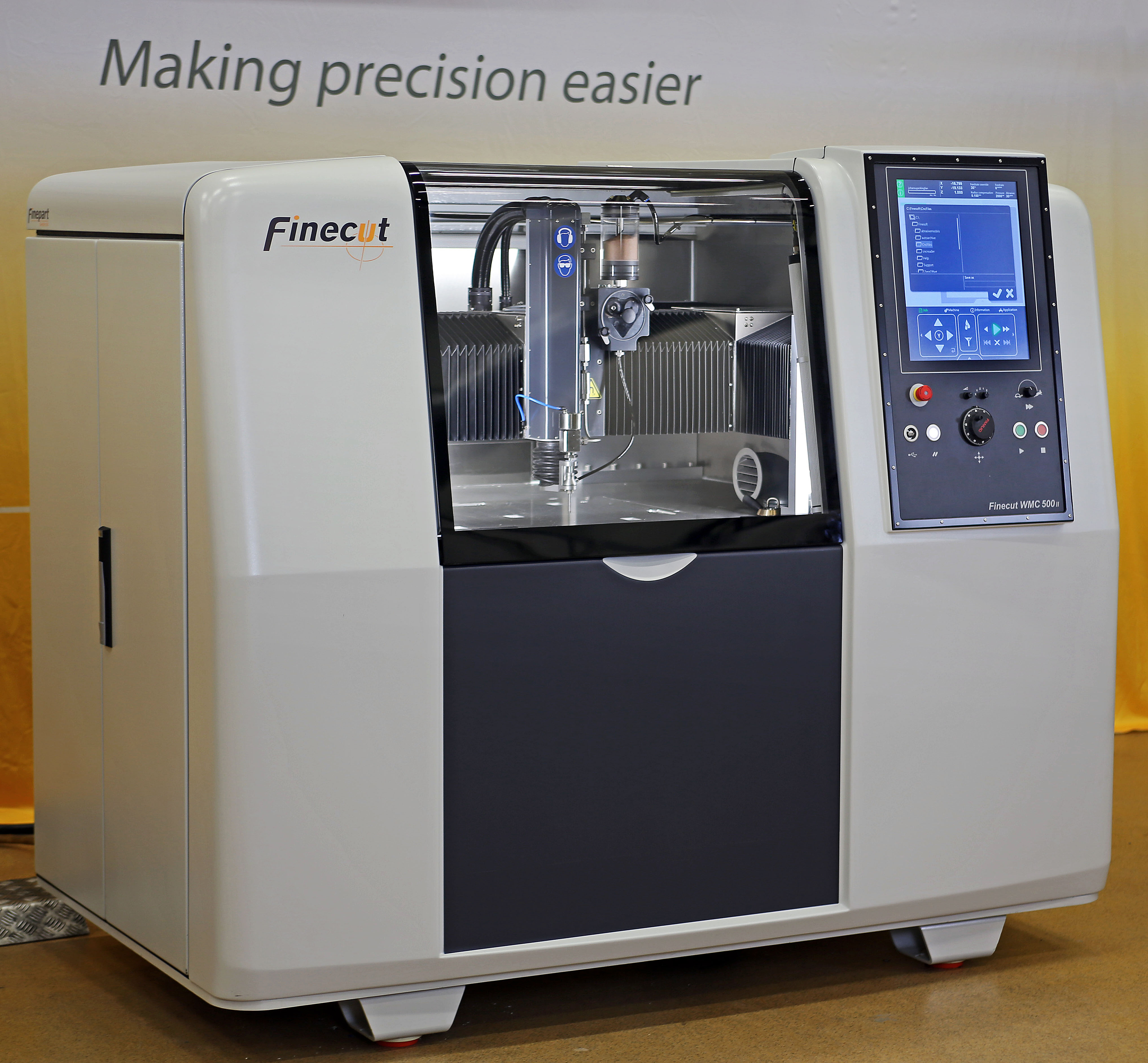

Waterjet cutting machines have traditionally been large, overpowering and substantial pieces of kit which take up a huge amount of space on the workshop floor and for many businesses, the size requirement has made it prohibitive. But Finepart’s Micro Abrasive Waterjet is redefining the definition in terms of both size and accuracy.

It defies conventional norms with its sophisticated yet compact design which brings with it finesse, sensitivity and very high accuracy. This article explores the benefits of the micro-abrasive water jet and why it is a valuable addition to any precision engineering company.

The micro abrasive waterjet is simple to use with an intuitive interface that enables users to operate it effectively without the need for advanced CNC machining skills. It also produces a burr free finish and is simple and cost-effective to set up. The enhanced accuracy, higher cutting speed and intricate cut capabilities translate to superior productivity, wider potential applications and ultimately higher profits. Other benefits include:

Rainford has more than three decades of expertise and has formed partnerships with world leaders in the precision tooling industry. We are ISO 9001 certified and pride ourselves on strong communication and excellent customer service. We can employ our extensive knowledge and experience to tailor a solution that meets your expectations and budget.

Reach out to Rainford Precision to unlock the full potential of micro abrasive waterjet technology in your operations. Get in touch with our expert team for a no-obligation consultation today!

%2c%20vA0.jpg)

Finepart’s Cutting-Edge Micro Abrasive Waterjet Technology, Supplied by Rainford Precision

1 min read

Rainford To Launch Micro Abrasive Waterjet Machine at Advanced Engineering 2017 On Stand L1 at Advanced Engineering, micro machining specialists...

Rainford Precision will highlight its reputation as a leader in ultra-high precision micro-machining at the forthcoming Medical Technology Ireland...