Why Custom Cutting Tools Matter In Precision Engineering

Accuracy is synonymous with precision engineering and while standard tools can deliver acceptable results, they often fall short when absolute...

2 min read

Rainford Precision : Dec 23, 2025 10:00:00 AM

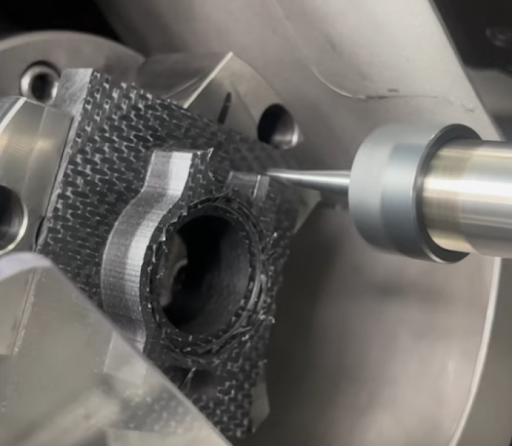

Composite materials can be particularly hard to machine because of the mixed and abrasive fibres they comprise of. Composites like CFRP (carbon fibre reinforced polymer), GFRP (glass fibre reinforced polymer) and glass ceramics are notoriously abrasive and demanding on tooling. Selecting the wrong cutting tool can lead to excessive wear and tear, unexpected breaks and poor finishes.

Two of the most popular materials for tackling these challenges are PCD (Polycrystalline Diamond) and CVD-D (Chemical Vapour Deposited Diamond). But which one offers the best performance, and the best value, for your application?

PCD is made from sintered diamond particles bonded with a metallic binder. This structure provides good toughness, resistance to impact and excellent heat dissipation, making it a reliable option for a broad range of non-ferrous and abrasive materials.

In contrast, CVD-D is a binderless material consisting of pure diamond layers grown directly onto a substrate. Without a soft metal phase, it delivers exceptional hardness, edge sharpness, and wear resistance, outperforming PCD in some applications, especially under extreme temperatures and abrasive loads.

When you work with highly abrasive materials like CFRP or glass ceramics, CVD diamond tools typically outperform PCD in tool life by a factor of five to 10 times. This means fewer tool changes, less downtime and greater productivity which are all key considerations when it comes to maximising your operational efficiency.

That said, in less abrasive applications such as machining aluminium alloys with less than 10% silicon content, PCD offers a more cost-effective alternative as the performance gap between the two narrows. In these scenarios, the lower initial cost of PCD diamond tooling options can justify their selection.

One of CVD-D’s headline benefits is its ability to maintain sharp cutting edges without micro-chipping, even when machining delicate or layered composites. This results in superior surface finishes, making it the preferred choice when edge fidelity and finish quality are critical such as in aerospace components, medical devices, or optical assemblies.

PCD, while tough and thermally stable up to around 750°C, can suffer from gradual edge degradation under high-friction conditions, which may compromise both accuracy and finish over time.

It’s true that CVD-D tools carry a higher upfront cost, but this investment often pays off in the long run. Thanks to extended tool life and consistent performance, cost-per-part is typically lower in high-volume or high-precision composite machining applications.

PCD tools, while more affordable initially, may require more frequent replacement and can introduce variability in results, particularly when used beyond their optimal material range.

As is often the case in precision tooling there is no single answer and ultimately it boils down to the application. The composite machining tool you choose will be dictated by material being machined.

For high-abrasion, high-precision composite machining (e.g., CFRP in aerospace or glass ceramics in optics), CVD-D is the superior choice for both performance and finish. For general-purpose machining of less abrasive non-ferrous materials, PCD provides a more budget-friendly option without significantly compromising performance.

Confused about which diamond tool is right for your composite application? Stop guessing and start optimising. Contact the team at Rainford Precision today!

Accuracy is synonymous with precision engineering and while standard tools can deliver acceptable results, they often fall short when absolute...

Medical manufacturing is meticulous in its detail, taking years of research and development for products to reach market. The types of equipment that...

A Partnership Built on Expertise and Unmatched Service Support with Rainford’s reputation for technical excellence, leveraging manufacturer-trained...