Your Micro And High Precision Cutting And Machine Specialist

Since 1991, Rainford Precision Machines have supplied the precision engineering industry in the UK and Ireland with machines and cutting tools of the highest calibre.

The Sole Agent For Kern In The UK And Ireland

If you're seeking to upgrade your business's equipment to enhance consistency and reliability, Rainford are here for you

Expert Precision Drilling

Founded in 1991 by Arthur and Pauline Turner, Rainford Precision has become synonymous with providing high-precision engineering solutions through top-tier machines and cutting tools. In May 2019, Miles Evans and Hazel Burgess assumed leadership, committed to expanding the company's offerings and services while building on its solid foundation. With a wealth of engineering expertise, the Rainford team excels in machining a diverse range of materials, including tungsten carbide, glass, ceramics, steels, exotics, aluminum, and everything in between.

PRoviding Industry Leading Service

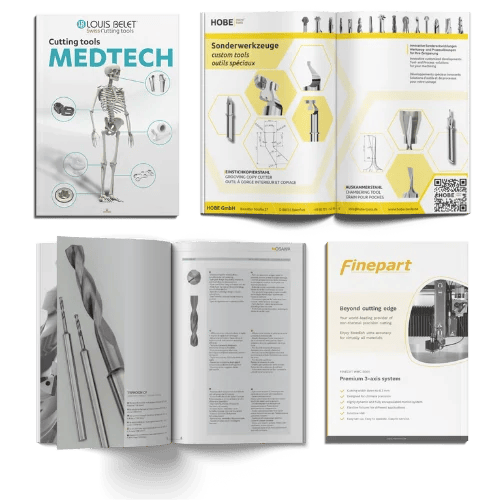

Special Design Cutting Tools

Are you seeking a special form or step drill, a tailor-made boring bar, or a custom form milling cutter to combine operations together? Your search ends with Rainford! Recognising that one size doesn't suit every need, we understand the drawbacks of relying on standard tools, which can often result in inefficient and unreliable processes.

Industries We Work With

Motorsport

Ignite performance in motorsport with our specialised tools. We accelerate precision for winning results on the track.

Nuclear

Elevate nuclear industry standards with our specialised tools powering excellence in every nuclear application.

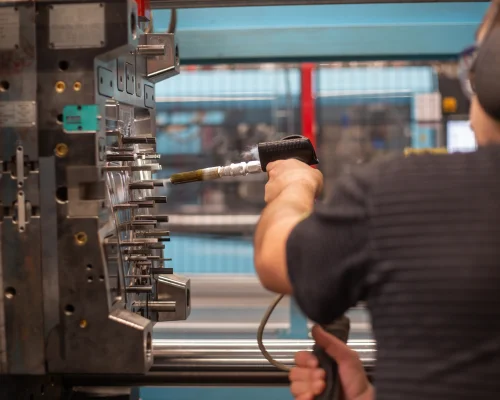

Mould & Die

Empower your mold and die processes with our custom drills, bespoke boring bars, and unique milling cutters.

Education

Transform education with our innovative solutions. Tailored tools and resources empower learning, shaping a brighter future for students and educators.

.webp)

Watchmaking

Precision redefined in watchmaking. Our custom tools, from drills to milling cutters, elevate craftsmanship, ensuring excellence in every intricate detail.

Aerospace

Soar to new heights in aerospace with our precision tools. From advanced drills to cutting-edge milling cutters, we propel innovation for superior performance in the aerospace industry.

Medical

Elevate medical precision with our specialized tools. From custom drills to advanced milling cutters, we empower excellence in healthcare innovation.

Defence

Defend with precision. Our specialised tools, from advanced drills to milling cutters, empower excellence in the defense industry's mission-critical applications.

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

.png?width=2563&height=2351&name=KERN-Ametek-logo-rot-schwarz%20(1).png)

.png?width=500&height=200&name=PEMtec%20Logo%20(1).png)

.png?width=500&height=200&name=Benzinger%20Logo%20(1).png)

Book A Consultation

Revolutionise your machine drilling operations today! Take the first step by booking a consultation and a member of our seasoned team will analyse and optimise your processes, recommending cutting-edge technologies for enhanced precision and productivity.

Latest From The Blog

2 min read

Machining Custom Medical Implants With The Kern Micro Vario

Apr 30, 2025 by Rainford Precision

2 min read

Fuelling Innovation In Medical Equipment Manufacturing With High Precision Cutting Tools

Apr 25, 2025 by Rainford Precision

2 min read

Louis Belet: Precision Tools For Every Stage Of Watchmaking

Apr 21, 2025 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)